Create a Quality Inspection Form

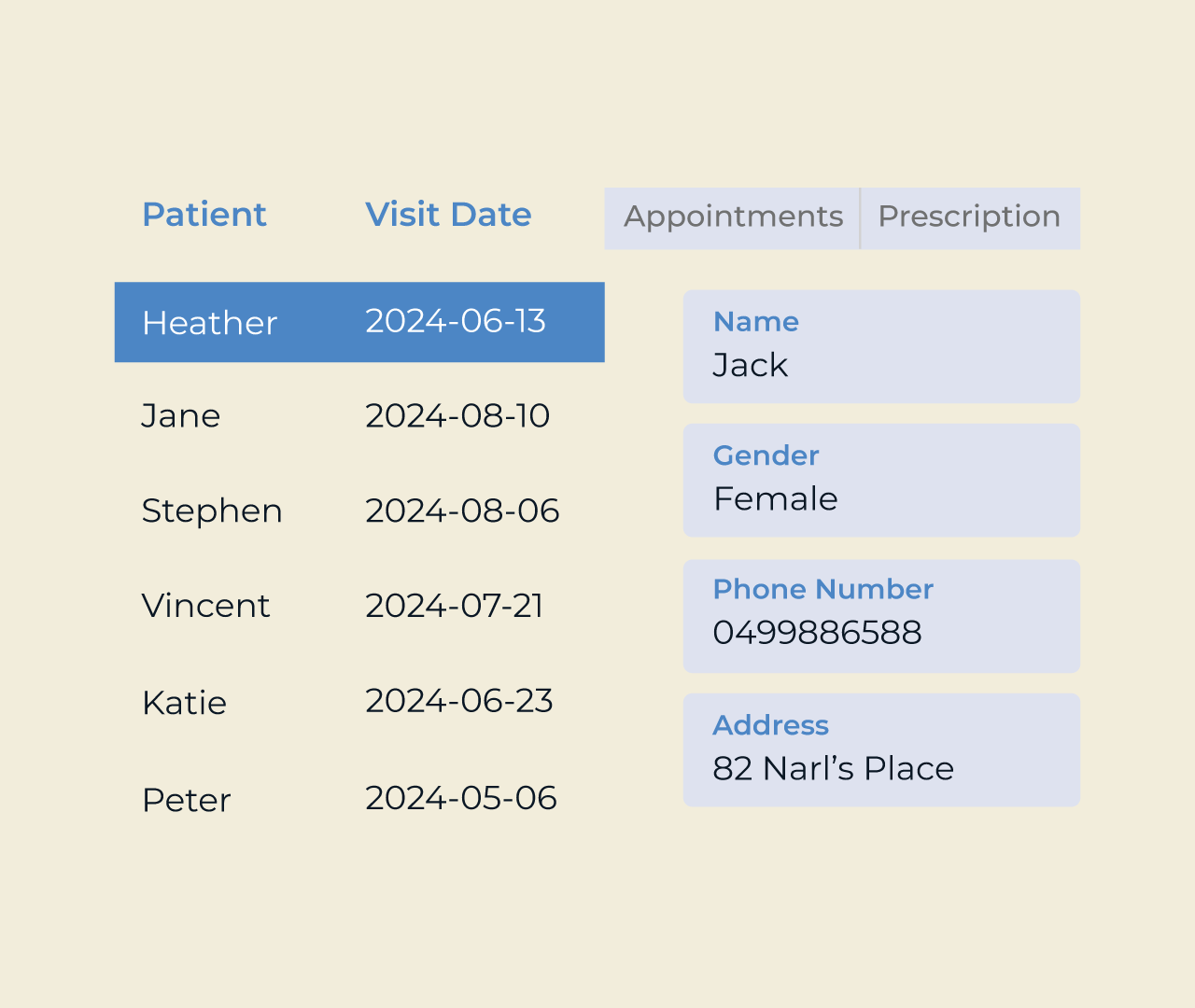

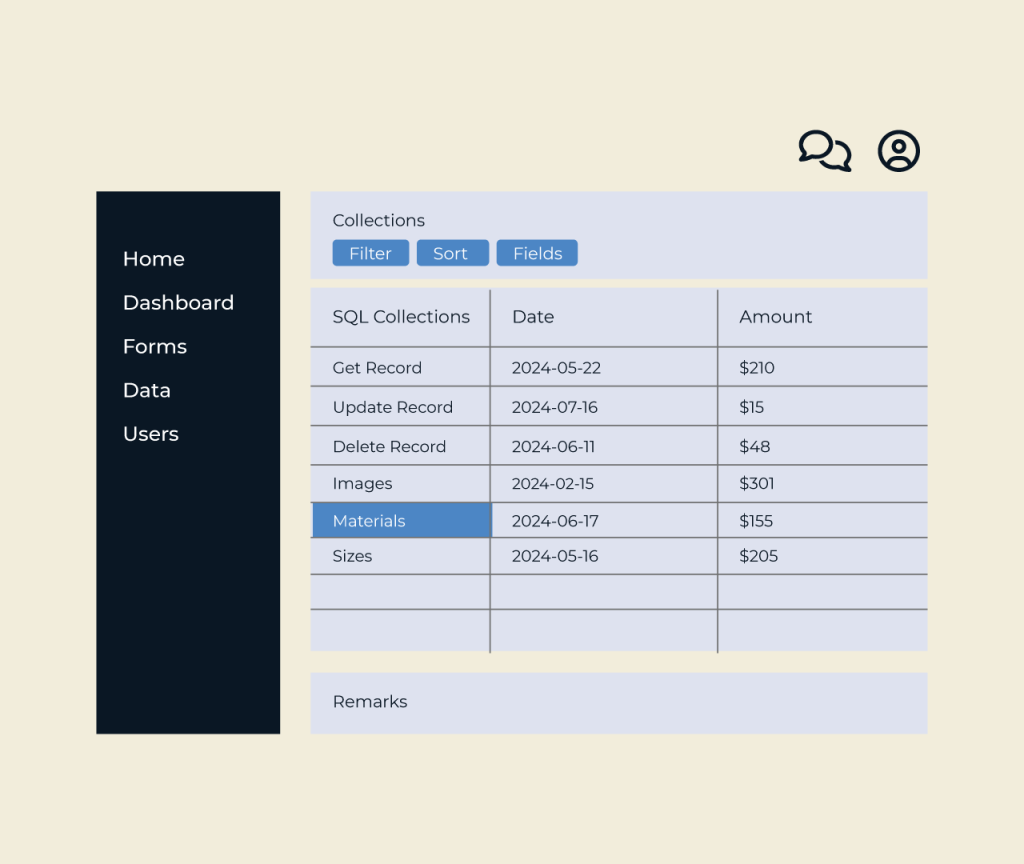

Creating a quality inspection form is essential for ensuring consistent product standards and compliance with specifications. Five provides an intuitive platform that enables users to design tailored forms easily. With customizable fields and options, you can incorporate checkboxes, text fields, and dropdown menus to capture all necessary inspection data effectively.

Using Five’s drag-and-drop interface, you can arrange the form elements according to your inspection workflow. This flexibility allows teams to adapt the form as processes evolve, ensuring that it remains relevant and efficient. Additionally, the ability to generate reports directly from the filled forms streamlines documentation and enhances overall quality control efforts.