The Ultimate Fleet Maintenance Checklist

The Ultimate Fleet Maintenance Checklist

For fleet managers and business owners, vehicle maintenance isn’t just about avoiding breakdowns—it’s about protecting your investment, ensuring safety, minimizing downtime, and controlling operational costs. A well-structured maintenance program built around a comprehensive checklist is the foundation of efficient fleet management. This fleet management checklist helps you optimize your fleet maintenance processes.

Why Your Fleet Needs a Structured Maintenance Checklist

Implementing a systematic approach to fleet maintenance offers numerous benefits that directly impact your bottom line:

✅ Reduced downtime: Every hour a vehicle spends in unplanned maintenance represents lost productivity and revenue. Regular maintenance prevents unexpected breakdowns that take vehicles off the road.

✅ Extended vehicle lifespan: With the rising costs of new vehicles, extending your fleet’s useful life has never been more important. Consistent care helps vehicles last significantly longer, maximizing your return on investment.

✅ Improved safety: Well-maintained vehicles dramatically reduce the risk of accidents caused by mechanical failures, keeping drivers, passengers, and others on the road safe.

✅ Better fuel efficiency: In an era of fluctuating fuel prices, efficiency matters more than ever. Properly maintained engines, correct tire pressure, and clean filters can significantly improve fuel economy.

✅ Lower repair costs: Preventive maintenance is consistently more cost-effective than reactive repairs. Catching small issues early prevents them from becoming expensive problems.

✅ Enhanced compliance: Transportation regulations continue to evolve and become more stringent. Regular maintenance helps meet regulatory requirements and avoid costly violations and penalties.

Five’s Ready-To-Use Fleet System

Our fully featured, scalable Fleet Management System lets you manage vehicles, drivers, maintenance and fuel logs intuitively and in one place. We designed our fleet management system specifically for teams like yours – giving you exactly what you need without overwhelming features you’ll never use.

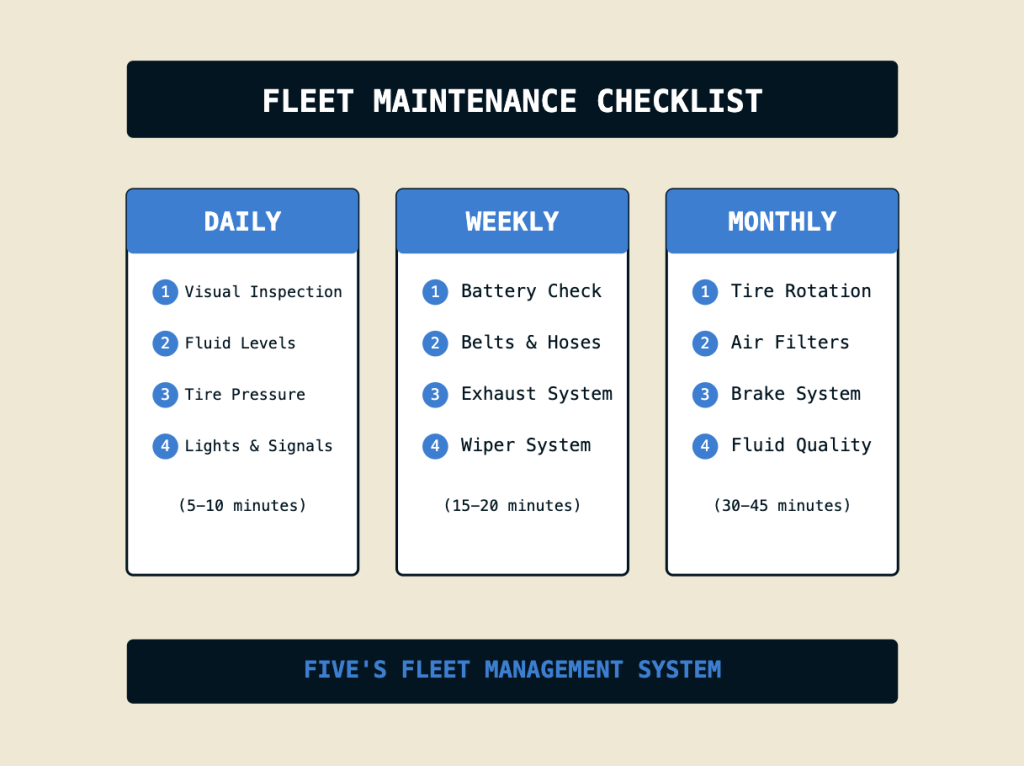

Comprehensive Fleet Maintenance Checklist

Daily Checks

Time: 5-10 minutes per vehicle

Frequency: Daily

Starting each day with quick inspections can prevent many problems before they start:

Visual inspection: Complete a 360-degree walk-around to identify obvious issues such as:

- Fluid leaks under the vehicle

- Tire damage or unusual wear patterns

- Body damage or new dents

- Loose or damaged components

- Broken lights or signals

- Windshield cracks or chips

Fluid Levels

Tire Condition:

- Pressure check (including spare) against manufacturer specifications

- Visual inspection for cuts, bulges, or embedded objects

- Tread depth using the penny test (insert a penny with Lincoln’s head upside down; if you can see the top of his head, the tread is too worn)

- Even wear pattern across the tire surface

Lights and Signals:

- Headlights (low and high beam)

- Brake lights and tail lights

- Turn signals (front and rear)

- Hazard lights

- Backup lights

- Marker lights and reflectors

- Interior dashboard lights

Weekly Checks

Time: 15 – 20 minutes per vehicle

Frequency: Weekly

A more thorough weekly inspection helps identify developing issues:

Battery Condition

Belts and hoses:

- Inspect for cracks, fraying, glazing, or softening

- Check for proper tension on accessible belts

- Look for leaks or seepage at hose connections

- Verify all clamps are tight and rust-free

- Pay special attention to radiator hoses when engine is cool

Exhaust system:

- Look for rust, holes, or damaged components

- Listen for unusual noises indicating leaks

- Check hangers and support brackets for security

- Ensure sufficient clearance from undercarriage components

Wiper operation:

- Test wipers at all speeds

- Check for streaking or skipping

- Verify washer fluid sprays correctly

- Inspect wiper arm tension

Monthly Checks

Time: 30 – 45 minutes per vehicle

Frequency: Monthly

These more substantial checks help maintain optimal performance:

Tire maintenance:

- Rotation according to manufacturer pattern (typically every 5,000-7,000 miles)

- Balance check if vibration is present

- Torque lug nuts to specification

- Alignment check if uneven wear is noticed

Air filtration system:

- Engine air filter inspection and replacement if dirty

- Cabin air filter check and replacement as needed

- Intake system inspection for loose connections

- Cleaning of air filter housing if necessary

Brake check:

- Visual inspection of pad thickness (where visible)

- Check for unusual noises during braking

- Test pedal feel for sponginess or excessive travel

- Inspect visible brake lines for leaks or damage

Fluid quality checks:

- Assess oil clarity and condition

- Check coolant color and concentration with test strips

- Verify transmission fluid color and smell

- Test brake fluid moisture content

Quarterly Checks

Time: 1h per vehicle

Frequency: Quarterly

These deeper inspections focus on critical systems:

Complete brake system inspection:

- Remove wheels to check pad/shoe thickness

- Measure rotor/drum thickness and check for scoring

- Inspect calipers/wheel cylinders for leaks or sticking

- Test brake fluid for contamination and replace if needed

- Verify proper operation of parking brake

Suspension and steering:

- Check ball joints and tie rod ends for excessive play

- Inspect shock absorbers/struts for leakage or damage

- Test steering response and return to center

- Look for unusual tire wear indicating alignment issues

- Inspect bushings for deterioration

- Lubricate all grease fittings

Fuel system maintenance:

- Replace fuel filter according to schedule

- Inspect fuel lines for leaks, cracks, or rubbing

- Check for fuel pump noise or long cranking

- Consider fuel injector cleaning service if performance has decreased

- Test fuel cap seal integrity

Cooling system inspection:

- Pressure test for leaks

- Test coolant freeze/boil protection level

- Inspect water pump operation

- Check radiator and heater core for obstructions

- Verify thermostat operation

- Test cooling fans for proper cycling

Semi-Annual Checks

Time: 2h to 3h per vehicle

Frequency: Every six months

These twice-yearly inspections help ensure long-term reliability:

- Electrical system diagnostics:

- Complete battery load test

- Alternator output check

- Starter current draw test

- Check for parasitic draws

- Inspect all wiring harnesses for chafing or damage

- Test all electronic accessories and systems

- Drivetrain inspection:

- Check differential fluid level and condition

- Inspect CV joints and boots (if equipped)

- Check transmission mount condition

- Inspect driveshaft universal joints

- Verify proper operation of 4WD/AWD systems

- Check transfer case fluid (if applicable)

- HVAC system service:

- Test air conditioning performance

- Check heating system operation

- Replace cabin air filter

- Inspect refrigerant level

- Clean condenser and radiator fins

- Verify proper operation of temperature controls

- Advanced diagnostics:

- Perform computer diagnostic scan for trouble codes

- Monitor live data parameters for out-of-spec values

- Check emission system operation

- Verify proper functioning of all sensors

- Test battery management system (for hybrid/electric vehicles)

Annual Checks

Time: 4+ hours per vehicle

Frequency: Once per year

Comprehensive yearly checks maintain long-term reliability:

- Complete vehicle inspection:

- Thorough inspection of all major systems

- Comprehensive fluid change program

- Full drivetrain assessment

- Steering system inspection

- HVAC system evaluation

- Chassis and undercarriage inspection

- Emissions and efficiency testing:

- Formal emissions testing for compliance

- Fuel economy baseline establishment

- Exhaust system integrity check

- Vapor recovery system inspection

- Oxygen sensor performance evaluation

- Catalytic converter efficiency testing

- Safety systems verification:

- Test all airbag system indicator operation

- Verify ABS system performance

- Check stability control operation

- Test backup cameras and sensors

- Ensure all safety restraints function properly

- Verify operation of all warning lights and systems

- Documentation and record review:

- Update complete maintenance history

- Review service intervals for all components

- Plan preventive replacements based on age/mileage

- Audit repair expenditures for unusual patterns

- Update warranty status for components

- Plan budget for upcoming maintenance needs

How Modern Fleet Management Systems Support Your Maintenance Program

Implementing an effective maintenance program becomes significantly easier with the right technology. Five’s Fleet Management System integrates seamlessly with the maintenance checklist approach outlined above, helping fleet managers transform maintenance from a reactive burden into a strategic advantage.

Streamlining Daily Vehicle Inspections

Daily vehicle checks are essential but can be time-consuming without the right tools. With a modern fleet management system:

- Drivers can complete digital pre-trip inspections through mobile apps

- Photos of potential issues can be captured and submitted instantly

- Fleet managers receive immediate notifications of critical problems

- Inspection history creates a digital trail for each vehicle

- Recurring issues are flagged for more comprehensive investigation

Automating Maintenance Scheduling

Never miss critical maintenance with intelligent scheduling features:

- Set up maintenance triggers based on mileage, engine hours, or calendar dates

- Receive automatic notifications when services are due

- Schedule preventive maintenance during natural operational downtime

- Track maintenance compliance across your entire fleet

- Generate maintenance forecasts for better resource planning

Enhancing Driver Participation

Drivers are your first line of defense against vehicle problems:

- Enable easy submission of maintenance alerts through driver portals

- Create accountability with digital tracking of driver vehicle care

- Simplify trip logging and vehicle condition reporting

- Provide drivers with access to vehicle maintenance history

- Recognize drivers who consistently follow maintenance protocols

Making Data-Driven Decisions

Transform maintenance data into actionable insights:

- Track maintenance costs per vehicle, department, or entire fleet

- Identify vehicles with abnormal maintenance patterns

- Compare performance across vehicle makes and models

- Monitor the effectiveness of maintenance providers

- Calculate the true cost of ownership for each asset

When considering solutions like Five’s Fleet Management System, look for features that specifically address your maintenance challenges while providing an intuitive interface that encourages organization-wide adoption.

Five’s Ready-To-Use Fleet Management System

Our fully featured, scalable Fleet Management System lets you manage vehicles, drivers, maintenance and fuel logs intuitively and in one place. We designed our fleet management system specifically for teams like yours – giving you exactly what you need without overwhelming features you’ll never use.

Using Technology for Better Fleet Maintenance

Modern fleet management systems have transformed how businesses approach maintenance. Five’s Fleet Management System offers a comprehensive solution that addresses these critical needs:

✅ Vehicle Tracking Dashboard: Monitor your entire fleet, maintenance schedules, and driver assignments in one intuitive central location. This eliminates the guesswork of knowing which vehicles need attention and when.

✅ Digital Maintenance Approvals: Review and approve service requests with a single click from anywhere. This streamlines decision-making and reduces maintenance delays that can impact operations.

✅ Self-Service Driver Hub: Empower your drivers with an intuitive platform to manage logs, reports, and maintenance requests. This creates accountability and ensures issues are reported promptly before they escalate.

✅ Custom Reports: Generate meaningful insights on fuel usage, vehicle performance, and other key metrics to make data-driven fleet decisions. Identify trends before they become problems.

✅ Fully Customizable System: Tailor the solution to your specific operational needs, including unique vehicle metrics tracking and maintenance workflows that match your existing processes.

Users of Five’s Fleet Management System report significant operational improvements including fewer fuel receipt discrepancies, substantial time savings on vehicle assignment logistics, faster identification of vehicles needing maintenance, and improved driver accountability across their fleets.

What sets this solution apart is how easily drivers can log trips, submit maintenance alerts, and access vehicle information through one simple interface that works immediately. This increased engagement from drivers creates a more proactive maintenance culture throughout your organization.

Conclusion

A well-implemented fleet maintenance checklist isn’t just about ticking boxes—it’s about creating a culture of proactive care that extends vehicle life, improves safety, and reduces costs. By following these guidelines and leveraging modern management systems like Five’s Fleet Management System, you can keep your fleet running at peak performance while controlling expenses and minimizing downtime.

The most successful fleet operations view maintenance not as an expense but as an investment that generates significant returns through reduced operating costs, improved reliability, and extended asset life. By implementing comprehensive maintenance practices and utilizing an intuitive, centralized management system, your organization can achieve the optimal balance of cost control and operational excellence.

Whether you manage a small business fleet or oversee dozens of vehicles, combining structured maintenance practices with a scalable fleet management solution will help protect your investment and optimize your operations for years to come.

Ready to transform your fleet maintenance operations? Sign up today for Five’s Fleet Management System and experience how an intuitive, fully-featured fleet solution can streamline your maintenance processes, reduce costs, and keep your vehicles performing at their best.