Mining Fleet Management Systems: Complete Guide

Your mining equipment fleet represents both your biggest investment and your greatest operational challenge. Modern mining fleet management systems have evolved from simple tracking tools to comprehensive platforms that can transform productivity, safety, and profitability across your entire operation.

What Exactly Is a Mining Fleet Management System?

At its core, a mining fleet management system (FMS) is specialized software designed to coordinate, monitor, and optimize the heavy equipment that forms the backbone of mining operations. We’re talking about haul trucks, excavators, loaders, dozers, drills, and all the other specialized vehicles that keep a mine running.

These systems go far beyond basic GPS tracking. Today’s mining FMS platforms integrate real-time data from multiple sources to provide complete operational visibility and control. They help dispatchers make smarter decisions, allow managers to identify inefficiencies, and give operators the information they need to work safer and more effectively.

Choosing the Right Provider for Your Operation

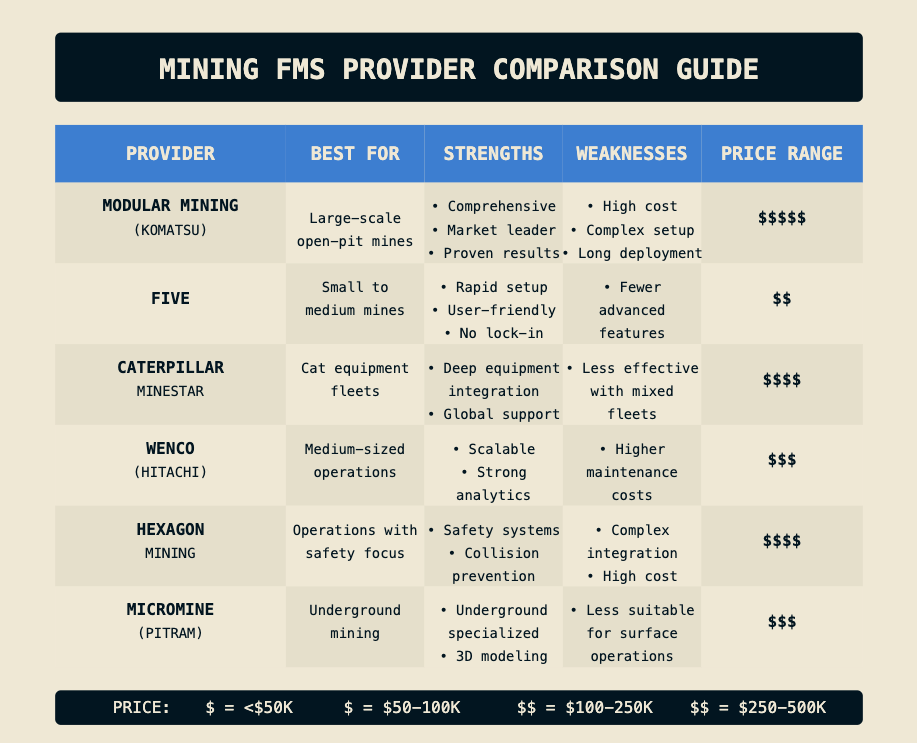

Not all mining fleet management systems are created equal. The market offers several established providers, each with different strengths and focus areas:

- Modular Mining (Komatsu) offers comprehensive solutions ideal for large open-pit operations but comes with higher costs and complexity.

- Five’s System targets small to medium operations with rapid setup, user-friendly interfaces, and no long-term contracts, though it offers fewer advanced features than enterprise solutions.

- Caterpillar MineStar provides excellent integration with Cat equipment but may be less effective for mixed fleets.

- Wenco (Hitachi) delivers scalable solutions with strong analytics capabilities suitable for mid-sized operations.

- Hexagon Mining combines fleet management with advanced safety systems, particularly collision prevention tools.

- Micromine (Pitram) specializes in underground mining with 3D modeling capabilities but is less suitable for surface operations.

Deeper Dive Into Your Fleet Options

Five’s Fleet Management – Fast and Flexible

Five targets smaller operations that need results quickly. Our approach centers on getting you operational within 30 rather than waiting over a year for full deployment.

The interface is straightforward. Your dispatchers can start using it effectively within days. The no-contract model means you can scale up or down based on actual needs without penalty clauses. This matters for shorter-life mines or operations dealing with volatile commodity prices.

You trade advanced features for simplicity and speed but the analytics are still solid. For operations running 20-50 pieces of equipment, this often makes sense. You get most of the productivity benefits without the complexity overhead.

Five’s Ready-To-Use Fleet System

Our fully featured, scalable Fleet Management System lets you manage vehicles, drivers, maintenance and fuel logs intuitively and in one place. We designed our fleet management system specifically for teams like yours – giving you exactly what you need without overwhelming features you’ll never use.

Five’s System – Our Fleet Management Approach

Let’s talk about what makes Five’s Mining System different from the traditional mining fleet management crowd. While the big players focus on enterprise-scale complexity, Five has built something that actually makes sense for the majority of mining operations out there.

The Philosophy Behind the Platform

Five’s system started with a simple observation: most mining operations spend months implementing fleet management systems, then use maybe 20% of the available features. Our response was to flip this model entirely. Instead of building everything possible and letting you figure out what matters, we identified the core functions that actually drive results and made those work perfectly.

Our vehicle tracking dashboard puts everything you need in one place. You can see where your vehicles are, which ones are due for maintenance, who’s driving what, and how your fuel costs are trending. It sounds basic, but the execution is what matters. The interface loads fast, updates in real-time, and doesn’t require ten clicks to find the information you need.

Where Five’s Really Shines

The digital maintenance approval system is a good example of our practical approach. Your maintenance team submits a request from their phone, you review it from yours, and the work gets scheduled automatically. No more paper forms, no more lost requests, no more wondering whether maintenance was approved or not.

The self-service driver hub addresses something that bigger systems often overlook: your drivers are the ones actually using the equipment every day. Five gives them a simple platform to log trips, report maintenance issues, and access vehicle information without having to go through dispatch for every minor request. Drivers can submit maintenance alerts directly when they notice something wrong, which means problems get flagged before they become breakdowns.

Custom Reports That Actually Matter

The reporting functionality focuses on metrics that directly impact your bottom line. Fuel usage reports show you which vehicles or drivers are burning through diesel faster than they should. Vehicle performance reports highlight machines that might need attention before they fail. The system tracks these patterns automatically and presents the data in formats that make sense for mining operations.

The Scalability Question

What’s interesting is our customization approach. Rather than trying to be everything to everyone out of the box, Five has built a platform that can be modified to fit your specific operation. Maybe you need to track tire pressure data, or you want maintenance workflows that match your existing processes. Our development team works with you to build exactly what you need instead of forcing you to adapt to our system.

The platform can handle small operations with a dozen pieces of equipment or larger operations with hundreds of vehicles. The key difference from enterprise systems is that complexity scales with your needs rather than being front-loaded during implementation.

If you start with basic vehicle tracking and maintenance scheduling, you can add features like advanced analytics, fuel management, or custom reporting modules as your operation grows. This approach lets you prove value with core functionality before investing in more sophisticated capabilities.

Five’s Ready-To-Use Fleet System

Our fully featured, scalable Fleet Management System lets you manage vehicles, drivers, maintenance and fuel logs intuitively and in one place. We designed our fleet management system specifically for teams like yours – giving you exactly what you need without overwhelming features you’ll never use.

Modular Mining (Komatsu) – The Enterprise Solution

Modular Mining handles the biggest operations in the world. We’re talking about mines with 200+ trucks where every decision affects millions in daily revenue. The system processes massive amounts of data and can optimize complex dispatch decisions across your entire fleet simultaneously.

The technology is genuinely advanced. It tracks equipment health, operator performance, fuel consumption, and maintenance schedules while running sophisticated algorithms that consider dozens of variables for each dispatch decision. You get detailed analytics on everything from tire wear patterns to fuel efficiency by operator.

The downside is complexity and cost. Implementation takes 12-18 months and requires dedicated IT resources. Licensing costs run into the millions for large operations. Your team needs extensive training to use the system effectively. But for operations that can handle this investment, the productivity gains are substantial.

Caterpillar MineStar – Equipment Integration Specialist

MineStar excels when your fleet is predominantly Cat equipment. The system connects directly to engine diagnostics, hydraulic systems, and maintenance schedules in ways third-party systems can’t match.

Equipment health monitoring is exceptional. The system predicts component failures weeks in advance by analyzing engine temperature patterns, hydraulic pressure variations, and transmission performance data. This prevents unexpected downtime and lets you schedule maintenance during planned shutdowns.

The limitation is mixed fleets. Most mines run equipment from multiple manufacturers. MineStar can manage mixed fleets, but you lose the deep integration advantages that make the system valuable. Non-Cat equipment gets basic functionality while Cat machines get the full treatment.

Wenco (Hitachi) – The Balanced Option

Wenco delivers enterprise capabilities without enterprise complexity. It works well for operations that have outgrown basic systems but aren’t ready for full-scale complexity.

Their analytics platform identifies productivity patterns that aren’t obvious from standard metrics. Maybe your night shift outperforms day shift when you account for different loading conditions. Or certain operator combinations consistently deliver better results. Wenco’s reporting surfaces these insights.

Implementation is well-structured. You start with basic dispatch functionality and add modules like equipment health monitoring or route optimization as your team gets comfortable with the system. This phased approach reduces risk and training overhead.

Hexagon Mining – Safety-Integrated Fleet Management

Hexagon builds safety technology directly into fleet management rather than treating it as an add-on feature. Their collision avoidance systems track equipment location and movement in real-time, predict potential collision paths, and can automatically intervene when necessary.

The safety capabilities extend beyond collision avoidance. The system monitors operator fatigue, tracks safety protocol compliance, and analyzes near-miss incidents to identify systemic risks. For operations where safety performance affects your operating license, these features are becoming essential.

The trade-off is that safety-first design sometimes compromises pure operational efficiency. Routes might be slightly longer to avoid high-risk areas, or speed limits might prioritize safety over maximum productivity. Most operations consider this acceptable, but it’s worth understanding.

Micromine (Pitram) – Underground Mining Focus

Pitram specializes in underground mining’s unique challenges. Surface mining is mostly about efficient material movement. Underground mining involves complex 3D navigation, ventilation requirements, and equipment constraints that surface systems aren’t designed to handle.

Their modeling optimizes truck routes through underground networks while considering tunnel dimensions, grade limitations, and ventilation requirements. The system understands that underground routes need to maintain proper airflow and avoid equipment conflicts in confined spaces.

Equipment tracking uses RFID, Wi-Fi triangulation, and other technologies since GPS doesn’t work underground. This matters for both efficiency and emergency response in environments where losing track of equipment or personnel has serious consequences.

The system doesn’t translate well to surface operations. The underground-specific complexity becomes unnecessary overhead for open-pit mines.

Making Your Fleet Management Decision

Here’s the reality: there’s no universal “best” fleet management system for mining operations. What works brilliantly for a 300-truck copper mine in Chile might be completely wrong for a 25-truck gold operation in Nevada. The key is understanding what your operation actually needs versus what sounds impressive in a sales presentation.

Start with your constraints. If you need something running within the next few months, enterprise solutions like Modular Mining are off the table regardless of their capabilities. If your budget won’t stretch to seven-figure licensing costs, that eliminates options too. If your team consists of three people wearing multiple hats, you need something that works without extensive training and support.